AI-powered cobots recognise the presence and orientation of their environment and parts to perform visual inspections and dynamic pick-and-place tasks.

An intuitive click-and-drag motion using our programming software reduces the complexity.

Inherent safety sensors will stop the AI Cobot when physical contact is detected, minimising the potential damage for a pressure-free and safe environment.

About Cobot EnterprisesWho We Are

Cobot Enterprises is at the forefront of collaborative robotics.

Founded with a vision to revolutionise the integration of humans and machines, we have been pioneering solutions that enhance productivity while ensuring human safety.

ServicesCreative features

for every industry

Collaborative Robots

Cobots provide a cost-effective, flexible, and safe automation solution that is suitable for manufacturers of all sizes, even for small to medium-sized businesses.

AI Vision

Cobots recognise the presence and orientation of their environment and parts to perform visual inspections and dynamic pick-and-place tasks.

Optical Inspection

Perform automated optical inspections of electronic components on a conveyor with high precision and accuracy

Welding Node

Optimise your welding processes with cobots to achieve optimal results efficiently with this solution.

3D Vision

An All-In-One solution, significantly reduces integration costs and efforts, maintenance and accountability issues.

Palletising Solutions

A highly reliable Robot Palletising Solution applicable to a Diverse Range of Industries

What we doWe have assembled the

best process to work with you

By entrusting cobots with monotonous tasks like loading or unloading components, human operators are liberated to address more intricate, high-value tasks.

By integrating cobots into palletising tasks, businesses can enhance efficiency, reduce the strain of repetitive lifting on workers, and achieve greater flexibility in adapting to different product lines and packaging types.

By incorporating cobots into processing tasks, businesses can augment precision, consistency, and efficiency, while simultaneously reducing the ergonomic risks associated with repetitive or strenuous activities.

Furnished with state-of-the-art sensors, cameras, and software, cobots can undertake meticulous inspection tasks, identifying defects or inconsistencies in products with remarkable precision and consistency.

By integrating cameras and sophisticated image analysis software, cobots can recognise shapes, patterns, colours, and even subtle defects in products. This fusion of vision and robotics allows cobots to undertake tasks that require a high degree of precision and adaptability, such as sorting items based on color or detecting minute flaws on a production line.

By employing cobots for welding, manufacturers can enhance precision, reduce the potential for human error, and alleviate workers from the hazards and strain associated with prolonged welding tasks.

Collaborative Robots for

automation

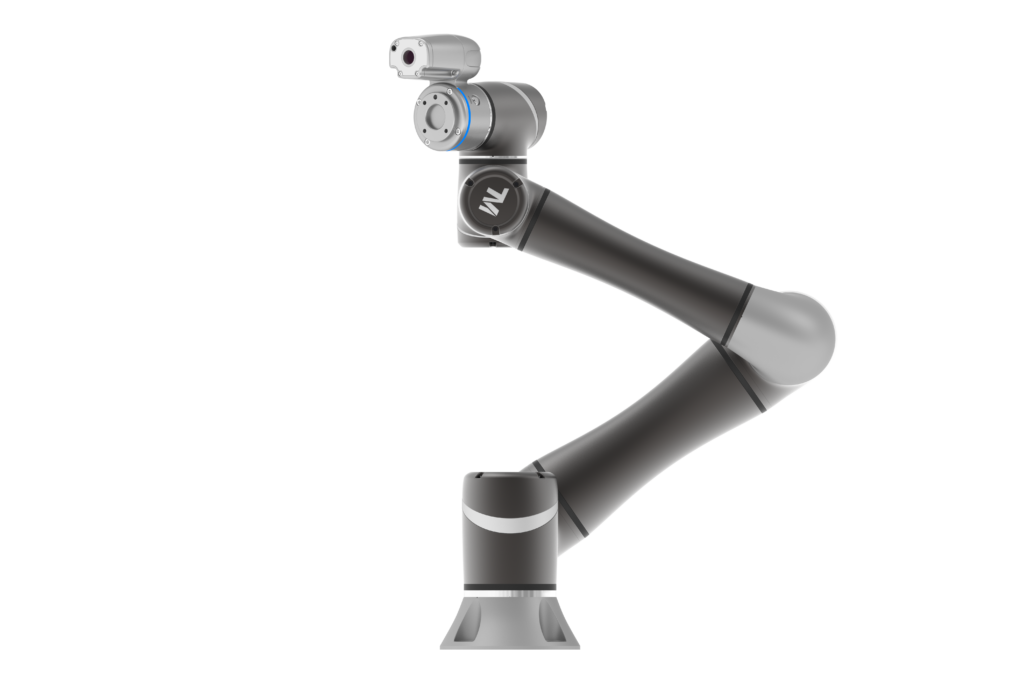

ProductsTM5-700 6-axis compact robotic arm.

The TM5-700 is our most compact cobot that can be easily integrated into any production line.

Designed with a built-in vision system specifically for flexible production needs required by small parts assembly, and production processes in consumer electronics and consumer goods. Our robot offers great versatility for small to medium-sized businesses. TM5-700’s size is also quick to deploy and easy to fit into existing factory environments.

- Reach: 700 mm

- Payload: 6 kg

- Weight: 22.1 kg

ProductsTM5-900 6-axis compact robotic arm.

The TM5-900 has the ability to “see” with an integrated vision that tackles assembly automation and inspection tasks with maximum flexibility.

Our collaborative robot can work with humans and share the same tasks, without compromising productivity or safety. It can give the highest level of precision and efficiency while being in the same workspace. The TM5-900 is ideal for the electronics, automobile, and food industries.

- Reach: 900 mm

- Payload: 4 kg

- Weight: 22.6 kg